Image Based Modeling, Measurement and Analysis

VOXELCON

case study 01 : Analysis Of The Complicated Shape Model

Outline

There are the following problem when you create FEM model from detail CAD model created as design data.

There are the following problem when you create FEM model from detail CAD model created as design data.

- Many Elements

-> It takes the time of calculation very much. - It is difficult to generate mesh, and it's need the tips and the experienced technique. In addition, the analysis result depends on mesh quality.

- In some cases, mesh generation fails.

But on the other hand, simplified model is...

- It takes time and labor to simplify.

- It is troublesome verifying the effect on the analysis accuracy by simplification.

These problems are solvable by voxel mesh generation technology of VOXELCON.

Even if the model is so complicated, the time and effort concerning analysis are curtailed by using VOXELCON.

Analysis Model

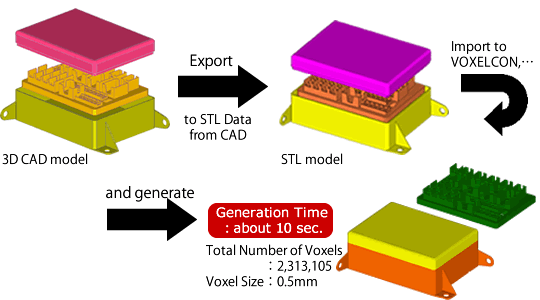

Flow of The Modeling

As it can generate mesh only by setting the number of divisions (Division Number of Each Axial Direction, Voxel Size, or Total Number of Voxels), anyone can generate voxel mesh.

Model Detail

Boundary Condition

Result : Static Stress Analysis

mises stress

Calculation Details

- Machine : Intel Xeon E5450 3.0GHz

(4CPU Parallel) - Analysis Time : 4 Hours 12minutes

- Memory : 777 MB

* Analysis time changes with a model dimension, model shape, boundary conditions, etc.

Comment

In this way, if you use voxel mesh generation technology of VOXELCON, you can create analysis model robustly and at high speed, even such a complicated, the mesh generation of which is difficult by a general Tetra mesher.

And, as the know-how or technique for mesh generation is unnecessary, anybody can create the same mesh for the same model. Therefore, it is useful also from a viewpoint of management of analysis accuracy.