Image Based Modeling, Measurement and Analysis

VOXELCON

Measurement

Basic function

- Length,Angle,Volume

- Center of Gravity

- Principal Axis Of Inertia

- Principal Moment Of Inertia

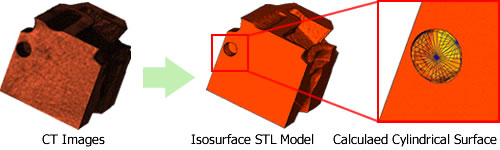

Approximate Shapes Calculation

It can calculate an approximate plane and an approximate cylindrical surface of arbitrary area by least squares method.

It is useful as actual thing measurement, if applied to isosurface STL model created from CT-images etc.

* Gunma Industrial Technology Center

Approximate Shapes

- Plane

- Cylindrical surface

- Conical surface

- Spherical surface

* These Approximate Shapes can be converted to IGES Data.

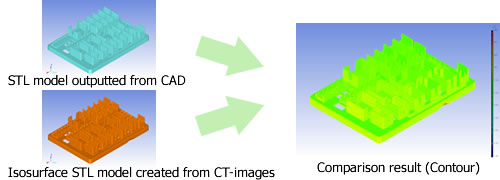

Comparing Shape Models

You can compare the shape of two STL models and can confirm the difference by contour. Comparing the shapes of CAD data to the actual thing data( created from CT-images etc. ) is utilizable for quality control. ( manufacture error evaluation, modification evaluation, etc ).

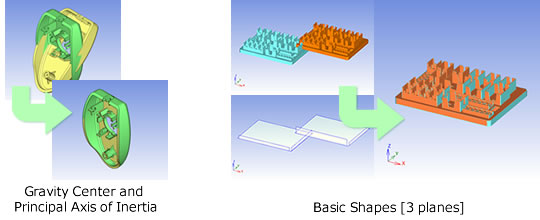

Automatic Alignment

It is necessary to align the position and posture of two models for various processings, such as "Comparing Shape Models" and "Modeling which combined two models".

VOXELCON has the function to align the position and posture of two models automatically as well as manually.

Using Gravity Center and Principal Axis of Inertia

It aligns automatically the position of gravity center and principal axis of inertia in each model.

This method is effective when the shape of two models is almost the same.

Using Basic Shapes

You can define approximate basic shapes (point, plane, cylinder) on two models, and align them. Alignment calculation has various ways (2 planes + 1 point, 1planes + 1 cylinder, etc...).

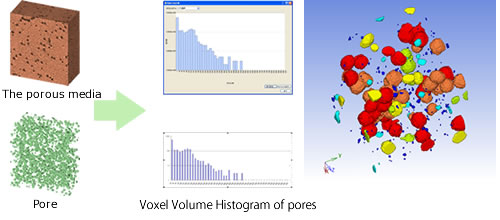

Voxel Volume Histogram, Coloring Clusters

The frequency distribution of the each clusters volume can be measured. And you can distinguish the clusters with the color according to volume.

It's useful to grasp the distribution situation of the size of extraneous materials, the particles in a matrix, and the size of a casting defect.

* Japan Fineceramics Center

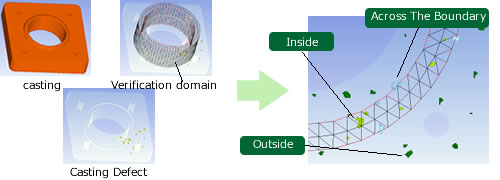

Evaluating Void Distribution

You can verify distribution of the cast defect included in the casting etc.

This is effective in quality control.